Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance

In today's manufacturing landscape, the efficiency and effectiveness of surface finishing processes are paramount, particularly in industries such as aerospace, automotive, and jewelry. Vibratory polishing machines have emerged as critical tools in achieving high-quality surface finishes while enhancing productivity. According to a recent report by the International Surface Finishing Association, vibratory polishing accounts for approximately 40% of all surface preparation applications, demonstrating its significant role in modern manufacturing.

Experts in the field, like Dr. Helen Carter, a renowned surface finishing specialist, emphasize the value of proper maintenance and optimal performance. She stated, "Unlocking the true potential of vibratory polishing machines not only enhances the quality of the finished product but also extends the lifespan of the machinery itself." This highlights the importance of understanding the intricacies of vibratory polishing machines for manufacturers seeking to improve their processes.

As we delve into tips for optimal performance and maintenance of vibratory polishing machines, we aim to equip operators and manufacturers with the knowledge required to maximize the benefits and ensure long-term reliability in their operations. Following proper guidelines can lead to improved efficiency and cost-effectiveness, ultimately giving businesses a competitive edge in their respective markets.

Maximizing Efficiency: Understanding the Ideal Cycle Times for Vibratory Polishing

When it comes to vibratory polishing machines, understanding the ideal cycle times is crucial for achieving maximum efficiency. Cycle times can significantly affect the quality of the polishing process and the overall productivity of operations. A cycle time that is too short may not allow for adequate surface finishing, while one that is too long can lead to unnecessary wear on components and reduced throughput. Generally, a cycle time of 30 to 60 minutes is a good starting point, but adjustments may be necessary depending on the material and desired finish.

To enhance performance, consider the following tips. First, monitor the consistency of the media and workpieces. Variations can impact the polishing results and lead to uneven wear. Second, regularly check and maintain the machine's settings, including vibration frequency and amplitude, as these parameters dramatically influence the polishing outcome. Lastly, keep an eye on the temperature during the cycle; overheating can compromise the integrity of both the media and the parts being polished. By fine-tuning these elements, operators can unlock the full potential of their vibratory polishing machines, ensuring quality and efficiency in their processes.

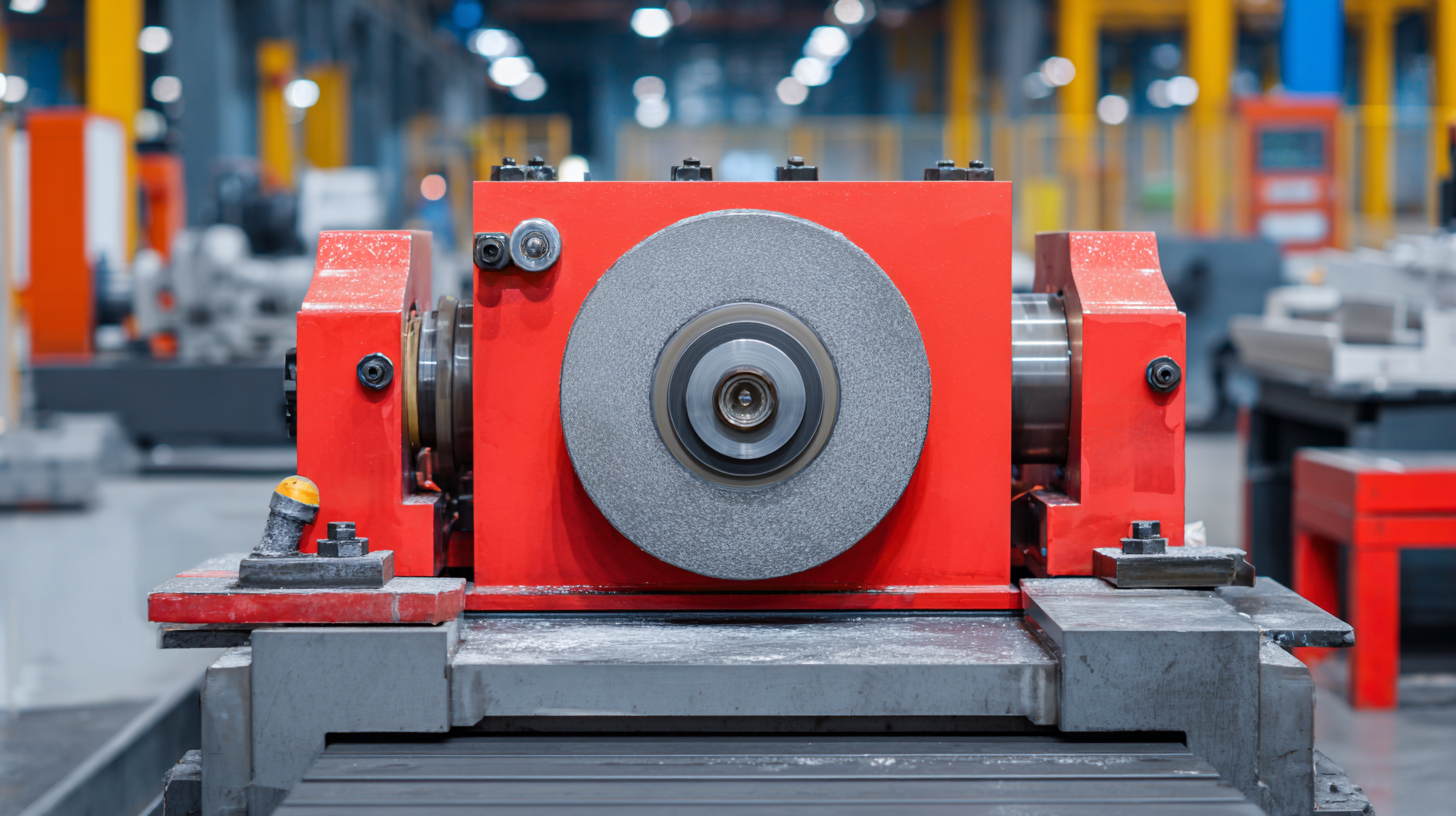

Unlocking the Potential of Vibratory Polishing Machines

This chart illustrates the optimal cycle times for different materials when using vibratory polishing machines, which can enhance performance and efficiency in polishing processes.

Material Selection: Choosing the Right Media for Different Finishing Applications

Selecting the right media for vibratory polishing applications is crucial for achieving optimal finishing results. The choice of media can significantly influence the surface quality and efficiency of the polishing process. For instance, according to a report by the American Machinist, using ceramic media can yield a smoother finish for hard materials like steel and titanium, enhancing their appearance and removing imperfections effectively. In contrast, softer materials such as plastic or rubber media are more suitable for delicate components, reducing the risk of damage while still providing a consistent finish.

Moreover, different applications necessitate varying media characteristics. For precision applications, the report highlights that angular media is preferred as it provides better cutting action, resulting in a quicker removal rate of surface material. In environments requiring less aggressive polishing, spherical media can be employed to achieve a high-gloss finish without the risk of scratching sensitive surfaces. Understanding the material compatibility and specific requirements of the items being polished is essential to leverage the full potential of vibratory polishing machines and ensure efficiency in production lines.

Monitoring Wear and Tear: Key Indicators for Maintaining Vibratory Polishing Machines

Monitoring the wear and tear on vibratory polishing machines is crucial for maintaining optimal performance and prolonging their lifespan. Key indicators include the condition of the bowls and liners, which can degrade over time due to constant friction and abrasive materials. Regular inspections should focus on checking for cracks, chips, or excessive wear. Any visible damage can lead to inefficient polishing and increased operational costs, making it imperative to address these issues promptly.

Another critical area to monitor is the motor performance, as abnormal sounds or vibrations often indicate underlying problems. Keeping an eye on the motor's temperature and ensuring it operates within the specified range can prevent overheating and subsequent failure. Additionally, the media used in polishing should be assessed for effectiveness; if the materials become too worn or ineffective, they can significantly hinder the polishing process. By implementing a routine maintenance schedule that includes these checks, operators can enhance the reliability and efficiency of their vibratory polishing machines.

Optimizing Settings: Balancing Amplitude and Frequency for Enhanced Results

When it comes to achieving optimal performance in vibratory polishing machines, fine-tuning the settings is crucial. The two primary parameters to focus on are amplitude and frequency. Amplitude refers to the height of the vibratory motion, while frequency denotes how often this motion occurs. Balancing these two elements effectively can lead to enhanced polishing results, a smoother finish, and reduced processing times.

Adjusting the amplitude is vital for different materials and desired finishes. A higher amplitude can achieve a more aggressive polishing effect, making it suitable for rougher surfaces. Conversely, a lower amplitude allows for a gentler finish, ideal for delicate items. Simultaneously, frequency adjustments can influence the energy distribution during the polishing process. Higher frequencies generally promote quicker polishing but may lead to increased wear on the machine and the polishing media. Striking the right balance between amplitude and frequency will help users maximize the efficiency and productivity of their vibratory polishing machines.

Routine Maintenance Best Practices: Extending the Lifespan of Your Polishing Equipment

Routine maintenance is critical in extending the lifespan and enhancing the performance of vibratory polishing machines. According to a study published by the Machinery Maintenance Association, regular maintenance practices can increase equipment life by up to 25%. This is particularly vital for polishing machines, which endure significant wear and tear due to constant vibration and mechanical movement. Implementing a routine maintenance schedule that includes daily inspections can help identify issues before they escalate, ensuring operations remain smooth and efficient.

Moreover, lubrication plays an essential role in minimizing friction between moving parts. A report from the Society of Manufacturing Engineers suggests that proper lubrication can reduce failure rates of machinery components by approximately 30%. Operators should regularly check lubricant levels and replenish them as needed, focusing on areas prone to excess wear. Cleaning the machine regularly to eliminate debris buildup is also critical, as dirt and dust can impair performance and lead to premature equipment failure. Prioritizing these best practices not only enhances the reliability of your vibratory polishing machine but also contributes to significant cost savings in the long run.