Top 10 Vibratory Polishing Machines for Perfect Finishing

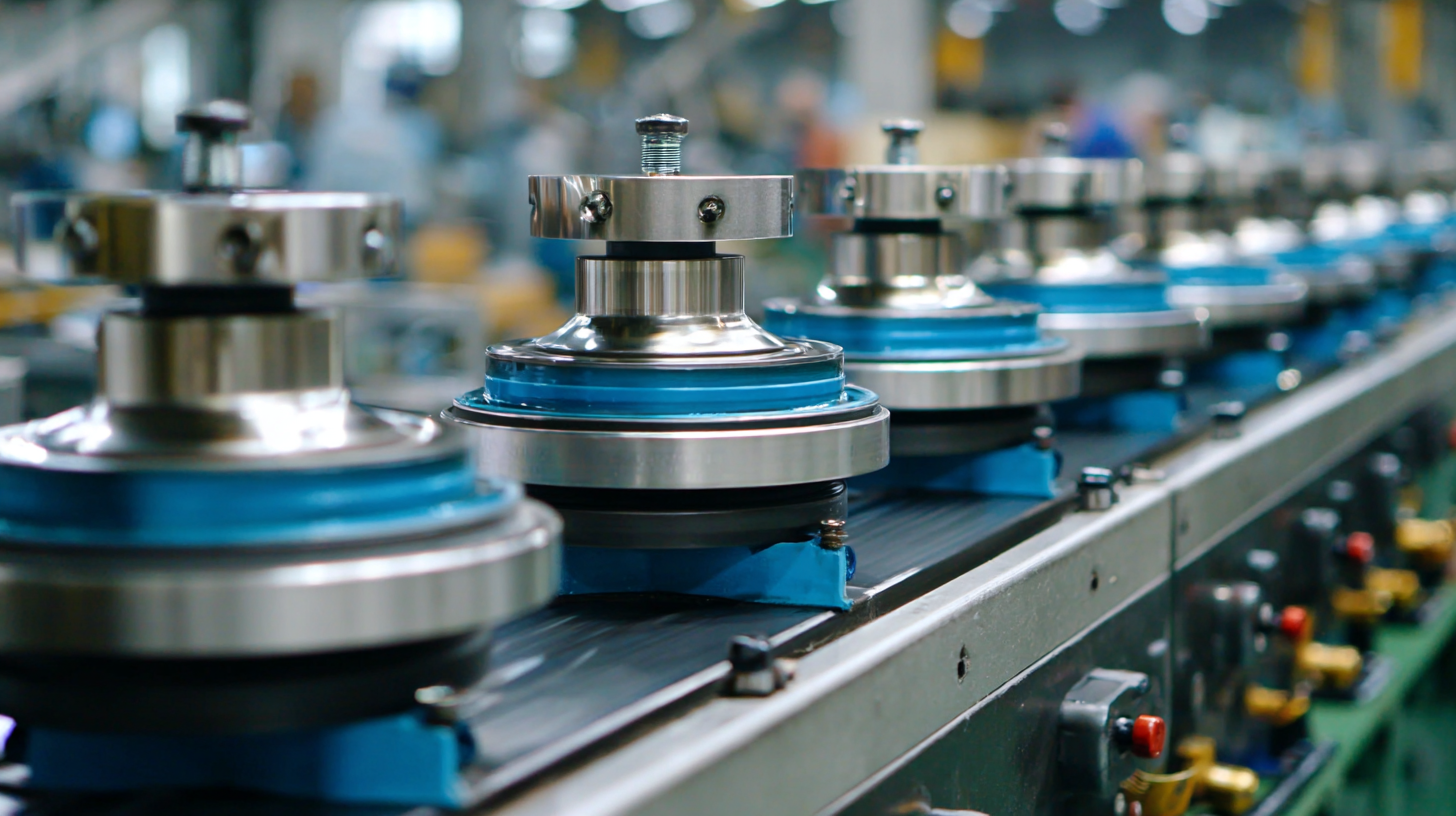

When it comes to achieving a flawless finish on various materials, using the right tools is essential. Among these tools, a vibratory polishing machine stands out for its efficiency and effectiveness in producing high-quality surfaces. Whether you are working with metals, plastics, or ceramics, the right vibratory polishing machine can significantly enhance your results by providing uniform polishing and reducing the chances of defects. In this guide, we will explore the top 10 vibratory polishing machines available on the market today, each designed to meet different requirements and applications, ensuring that you can find the perfect solution for your finishing needs.

In addition to reviewing these machines, we will provide valuable tips to help you maximize the potential of your vibratory polishing machine. By understanding the key features to look for and the best practices in operation, you can ensure that your investment yields optimal results. The combination of advanced technology and practical advice in this article will empower you to make informed decisions, whether you are a hobbyist or a professional in the finishing industry. Join us as we delve into the world of vibratory polishing and discover the machines that can take your finishing processes to the next level.

Vibratory Polishing Machines: An Overview of Industry Trends and Technological Advancements in 2025

In 2025, the vibratory polishing machine industry is poised for significant transformation, driven by advancements in technology and an increasing demand for precision finishing. According to a recent report by Market Research Future, the global vibratory finishing equipment market is projected to grow at a CAGR of 7.5% from 2022 to 2025, reflecting the rising adoption of automated solutions in manufacturing processes. This growth is largely attributed to the need for improved surface quality in various sectors, including automotive, aerospace, and electronics, where meticulous finishing is crucial.

As environmental concerns become more prominent, manufacturers are also focusing on sustainable practices. Many new vibratory polishing machines are integrating eco-friendly materials and technologies, such as non-toxic media and energy-efficient motors. A leading industry report by Grand View Research noted that the use of advanced digital controls and artificial intelligence in vibratory finishing systems enhances operational efficiency, reduces waste, and ensures consistency in results. These innovations are shaping the future of vibratory polishing, making it a pivotal process for industries striving for excellence in their production lines.

Top 10 Vibratory Polishing Machines for Perfect Finishing

| Machine Model | Vibration Frequency (Hz) | Load Capacity (kg) | Tank Size (L) | Power Consumption (kW) | Special Features |

|---|---|---|---|---|---|

| Model A | 30 | 150 | 200 | 1.5 | Automatic feeder |

| Model B | 35 | 200 | 250 | 2.0 | Noise reduction technology |

| Model C | 40 | 120 | 180 | 1.2 | Energy-efficient |

| Model D | 25 | 180 | 220 | 1.8 | User-friendly interface |

| Model E | 30 | 160 | 210 | 1.6 | Compact design |

| Model F | 28 | 140 | 190 | 1.4 | Multi-functional |

| Model G | 32 | 170 | 200 | 2.2 | High-speed processing |

| Model H | 36 | 190 | 230 | 1.9 | Precision control |

| Model I | 30 | 160 | 210 | 1.7 | Long-lasting materials |

| Model J | 34 | 200 | 240 | 2.5 | Easy maintenance |

Key Features to Consider When Choosing a Vibratory Polishing Machine for Optimal Performance

When choosing a vibratory polishing machine for optimal performance, there are several key features to consider. First, the size and capacity of the machine are crucial, as they determine the volume of workpieces it can handle. According to a report by Research and Markets, the global market for vibratory finishing machines is projected to grow at a CAGR of 5.6%, reflecting the increasing demand for efficient surface finishing solutions. A larger machine not only saves time but also allows for batch processing, improving overall productivity.

Another important factor is the control features of the machine. Advanced models offer adjustable amplitude and frequency settings, which help in achieving specific finishing results for different materials. For instance, a higher frequency can be used for delicate parts, while lower frequencies may be ideal for heavier materials. Investing in a machine with these capabilities can significantly enhance the finishing quality.

Tip: Always look for machines with a variety of media options, such as ceramic or plastic, as the right media can make a significant difference in surface finish and polishing effectiveness.

Additionally, durability and maintenance should not be overlooked. Machines made from high-quality materials are likely to have a longer lifespan and require less frequent repairs. Regular maintenance can ensure consistent performance and minimize downtime, which is vital for any production environment.

Tip: Opt for machines that come with a warranty and support from the manufacturer, as this provides peace of mind regarding the long-term operational efficiency of the equipment.

Top 10 Vibratory Polishing Machines for Perfect Finishing

Analysis of Market Leaders: Top Brands and Models for Vibratory Polishing Machines in 2025

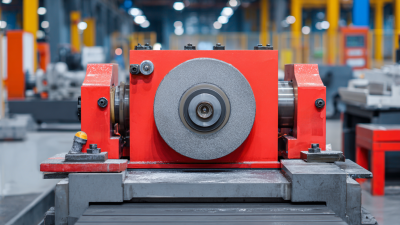

As we delve into the market for vibratory polishing machines in 2025, key players have emerged as frontrunners, significantly shaping the industry landscape. Reports from the International Journal of Manufacturing Technology highlight that the global market for vibratory polishing equipment is projected to grow at a CAGR of 5.6% from 2023 to 2028, driven by escalating demand from the automotive and aerospace sectors. These industries require superior surface finishes, making vibratory polishing machines essential for achieving high-quality outcomes.

Leading brands such as Deburring Machines Inc., Elma Schmidbauer GmbH, and OTEC Präzisionsfinish GmbH have distinguished themselves with innovative features like programmable polishing cycles and enhanced energy efficiency. For instance, the Elma E 300 series, renowned for its advanced ceramic media, optimizes processing times while improving surface quality, aligning with the industry's push towards sustainability and reduced operational costs. In 2025, as precision and efficiency remain paramount, these market leaders are set to redefine standards, ensuring that vibratory polishing machines not only meet but exceed the evolving expectations of manufacturers worldwide.

Cost-Effectiveness and Efficiency: Understanding the ROI of Vibratory Polishing Machines for Businesses

Investing in vibratory polishing machines can significantly enhance the efficiency and cost-effectiveness of finishing processes in a business. These machines streamline production by ensuring a uniform and high-quality finish on various components, reducing manual labor and minimizing waste. Understanding the return on investment (ROI) involves evaluating not only the initial purchase cost but also the long-term savings generated through increased productivity and lower operational costs.

Tips: When selecting a vibratory polishing machine, consider its capacity and the type of materials being polished. A machine that can handle higher volumes will yield better productivity rates, while the right media can optimize the finishing process, saving you time and resources. Additionally, regular maintenance of the equipment can prolong its lifespan and maintain performance, further enhancing your ROI.

Another key aspect is to analyze the energy consumption of the machines. Energy-efficient models can drastically cut down on utility costs, contributing to a more favorable ROI. Businesses should also look into the machine's versatility; a multifunctional unit can adapt to various polishing tasks, making it a valuable asset for any workshop looking to maximize both efficiency and profitability.

Safety Standards and Best Practices for Operating Vibratory Polishing Machines in the Workplace

Operating vibratory polishing machines in the workplace requires adherence to stringent safety standards and best practices to ensure a safe and efficient environment. First and foremost, it’s essential to conduct a thorough risk assessment before initiating any polishing task. This involves checking the equipment for any wear and tear, ensuring that all safety guards are in place, and verifying that the machine is properly grounded. Operators should be trained on emergency shutdown procedures and be familiar with the specific functions of the machine they are using.

Tips for safe operation include wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and ear protection. Additionally, ensure that the work area is well-ventilated to mitigate exposure to dust and fumes generated during the polishing process. Regular maintenance of the vibratory polishing machines is crucial to prevent malfunctions that could lead to accidents. Scheduling routine inspections and keeping the machines clean will enhance not only their performance but also the safety of the operators.

Moreover, it's beneficial to establish a clear communication protocol among team members working around the machines. This can include the use of hand signals or other forms of non-verbal communication to alert others to potential hazards. Encourage a culture of safety where employees feel empowered to report unsafe conditions or near-misses, fostering an environment that prioritizes safety and efficiency in the workplace.

Related Posts

-

Unlocking the Potential of Vibratory Polishing Machines: Tips for Optimal Performance and Maintenance

-

Top 10 UK Manufacturing Trends Transforming the Industry in 2023

-

Mastering Finishing Systems: A Comprehensive Guide to Enhancing Product Quality and Performance

-

Why Automation Machines Are Essential for Modern Manufacturing Success