How to Master Process Engineering Techniques for Improved Efficiency?

In the competitive field of process engineering, efficiency is critical. Renowned expert Dr. Jane Smith emphasizes, "Mastering process engineering techniques can revolutionize production." Her insight highlights a pressing industry need. Companies worldwide constantly seek innovative ways to enhance their workflows.

The landscape of process engineering is ever-evolving. Organizations often face challenges in reducing waste and improving output. Many professionals struggle to implement effective techniques, leading to frustration. The key lies in understanding both fundamental principles and advanced strategies. It’s essential to embrace a learning mindset. Continuous improvement is crucial.

Focusing on practical applications is vital. Some engineers may overlook the importance of small changes. Simple adjustments can yield significant results. Skills in process engineering can be cultivated over time. This journey demands dedication and resilience. By embracing both success and failures, engineers can drive meaningful changes in their organizations.

Understanding the Fundamentals of Process Engineering Techniques

Process engineering is a vital discipline that focuses on converting raw materials into valuable products efficiently. At its core, understanding the fundamentals means grasping key concepts like mass transfer, energy balance, and reaction kinetics. Each element intertwines to optimize production processes. For instance, effective mass transfer can reduce waste and increase yield. However, mastering these techniques requires ongoing learning.

It’s important to recognize that challenges arise. Not every process will yield the desired outcome on the first attempt. Sometimes, energy losses occur during transitions. Identifying these inefficiencies can be daunting. Moreover, engineers may overlook certain variables that impact performance. Regularly reviewing systems is crucial here, as it opens the door to innovation. Implementing small adjustments can lead to significant improvements.

The path to proficiency isn't linear. Engineers often need to revisit basic principles to troubleshoot effectively. Some techniques may seem outdated, yet they often serve as a foundation for new ideas. Process engineering thrives on experimentation and reflection. Embracing this cycle can illuminate the way to more efficient solutions.

Key Principles for Analyzing and Optimizing Processes

Process analysis and optimization are critical in any operation. Understanding the current performance is the first step. Gather data on workflows, resource allocation, and process times. Ensure you have accurate metrics. But remember, sometimes data can be misleading. Analyze it thoroughly to avoid false conclusions.

Once you have your insights, identify bottlenecks. Look for steps that slow down production or cause confusion. It’s common to overlook these problem areas. Involve team members in discussions. Their perspectives may reveal hidden issues. Collaboration often leads to better understanding and innovative solutions.

Next, think about process redesign. This does not always mean a complete overhaul. Small changes can yield significant improvements. Experiment with different strategies, like altering workflow sequences. Monitor the effects closely. Be prepared to adapt based on the results you see. Optimization is not a one-time task; it's an ongoing journey.

How to Master Process Engineering Techniques for Improved Efficiency

| Process Name | Efficiency (%) | Cycle Time (Minutes) | Cost ($) | Improvements Suggested |

|---|---|---|---|---|

| Process A | 85 | 30 | 1500 | Automate step 2 |

| Process B | 78 | 45 | 2000 | Reduce waste material |

| Process C | 90 | 25 | 1200 | Enhance training |

| Process D | 82 | 35 | 1700 | Upgrade equipment |

Tools and Technologies for Enhanced Process Efficiency

Process efficiency can be significantly improved by utilizing various tools and technologies. Automation is one of the key players. It reduces manual errors and streamlines operations. Utilizing sensors and real-time monitoring devices enhances oversight. These technologies allow for instant adjustments based on data. However, the initial setup can be complex and may require training. Many teams struggle with this transition.

Data analytics also plays a crucial role in optimizing processes. Collecting and analyzing data helps identify bottlenecks. Visualization tools can make patterns clearer. Yet, teams may overlook crucial metrics. This oversight can hinder improvement efforts. Continuous reflection on data insights is essential. Teams should invest time in understanding what the numbers truly indicate.

Lean management principles can further enhance process efficiency. They emphasize eliminating waste and improving workflow. Techniques like value stream mapping help visualize processes. But implementing these practices often requires shifts in company culture. Resistance to change can be a major hurdle. Acknowledging these challenges is the first step toward progress. Success demands consistent effort and a willingness to adapt.

Process Engineering Techniques for Improved Efficiency

Best Practices for Implementing Process Improvements

Implementing process improvements requires a strategic focus on best practices. According to a report from the Association for Manufacturing Excellence, organizations that adopt lean methodologies can achieve a 25% increase in efficiency over five years. Yet, many companies overlook the importance of employee involvement in these initiatives. Engaging staff at all levels fosters a culture of continuous improvement.

Data also shows that organizations investing in process training yield higher productivity. The American Society for Quality found that well-trained teams can boost process efficiency by up to 40%. Still, some businesses struggle with this. Resistance to change can undermine even the best strategies. A reflective approach involves understanding team dynamics and the challenges they face.

Lastly, monitoring key performance indicators (KPIs) is crucial. An alarming 70% of process improvement projects fail due to inadequate tracking. Regular evaluation helps identify areas for adjustment. It is essential to recognize that not every process improvement will yield immediate results. Some changes may take time to show effectiveness, leading to frustration among teams. It's vital to balance quick wins with long-term gains.

Case Studies: Successful Applications of Process Engineering Techniques

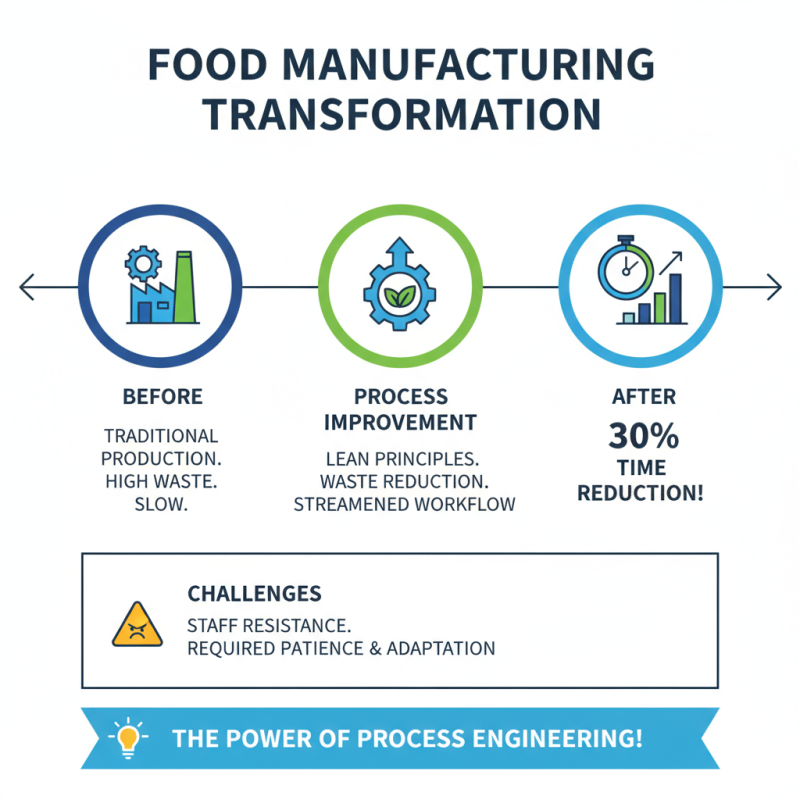

Case studies highlight the transformative power of process engineering techniques. In one instance, a food manufacturing company revamped its production line. They implemented lean principles, reducing waste and streamlining workflow. The result? A 30% decrease in production time. However, it wasn't a smooth journey. Initial resistance from staff created setbacks. Overcoming this required patience and adjustments to their strategy.

Another example is a pharmaceutical plant that adopted Six Sigma methodologies. They focused on minimizing defects in the production processes. After several rounds of trials, they achieved a significant reduction in errors. Yet, not every attempt was successful. Some processes faced unforeseen challenges, leading to temporary declines in output rates. These experiences taught the team valuable lessons about flexibility and continuous improvement.

In both cases, the emphasis on data-driven decision-making proved critical. Teams learned the importance of analyzing metrics regularly. Tracking performance allowed them to identify areas needing change. They faced hurdles but remained committed. This tenacity fostered an environment of innovation and growth. Ultimately, these case studies illustrate that mastering process engineering is not just about techniques; it's about resilience and adaptability.

Related Posts

-

What is Process Machinery and How Does it Work?

-

How to Succeed in Industrial Engineering with Essential Skills and Techniques

-

How to Use Automation Machines to Enhance Productivity in 2025

-

What is Home Engineering and How It Transforms Your Living Space

-

Top 10 Best Finishing Machines for Quality Print Finishing in 2023

-

What is an Automation Machine? Understanding Its Types and Applications