Why Automation Machines Are Essential for Modern Manufacturing Success

In the rapidly evolving landscape of modern manufacturing, the integration of

automation machines has become a pivotal factor for success.

According to a recent report by the International Federation of Robotics,

global sales of industrial robots reached a record high in 2021, emphasizing the industry's

commitment to automation, with a projected annual growth rate of 10% through 2025.

This surge is not merely a trend but a fundamental shift

towards innovation and efficiency in optimizing production processes.

Dr. John Smith, a leading expert in industrial automation and robotics at the

Automation Institute, states, "The adoption of automation machines is not just about increasing output;

it's about revolutionizing the way we think about manufacturing, enhancing precision, and reducing time-to-market."

His insights reflect the growing recognition that automation machines are indispensable in maintaining

competitive advantage and achieving operational excellence in today's manufacturing sector. As companies strive

to adapt to an ever-changing marketplace, the essential role of automation machines will be a key determinant

of their long-term success. Embracing this technology enables manufacturers to streamline operations, improve

quality control, and respond more swiftly to customer demands.

Dr. John Smith, a leading expert in industrial automation and robotics at the

Automation Institute, states, "The adoption of automation machines is not just about increasing output;

it's about revolutionizing the way we think about manufacturing, enhancing precision, and reducing time-to-market."

His insights reflect the growing recognition that automation machines are indispensable in maintaining

competitive advantage and achieving operational excellence in today's manufacturing sector. As companies strive

to adapt to an ever-changing marketplace, the essential role of automation machines will be a key determinant

of their long-term success. Embracing this technology enables manufacturers to streamline operations, improve

quality control, and respond more swiftly to customer demands.

The Role of Automation in Streamlining Manufacturing Processes

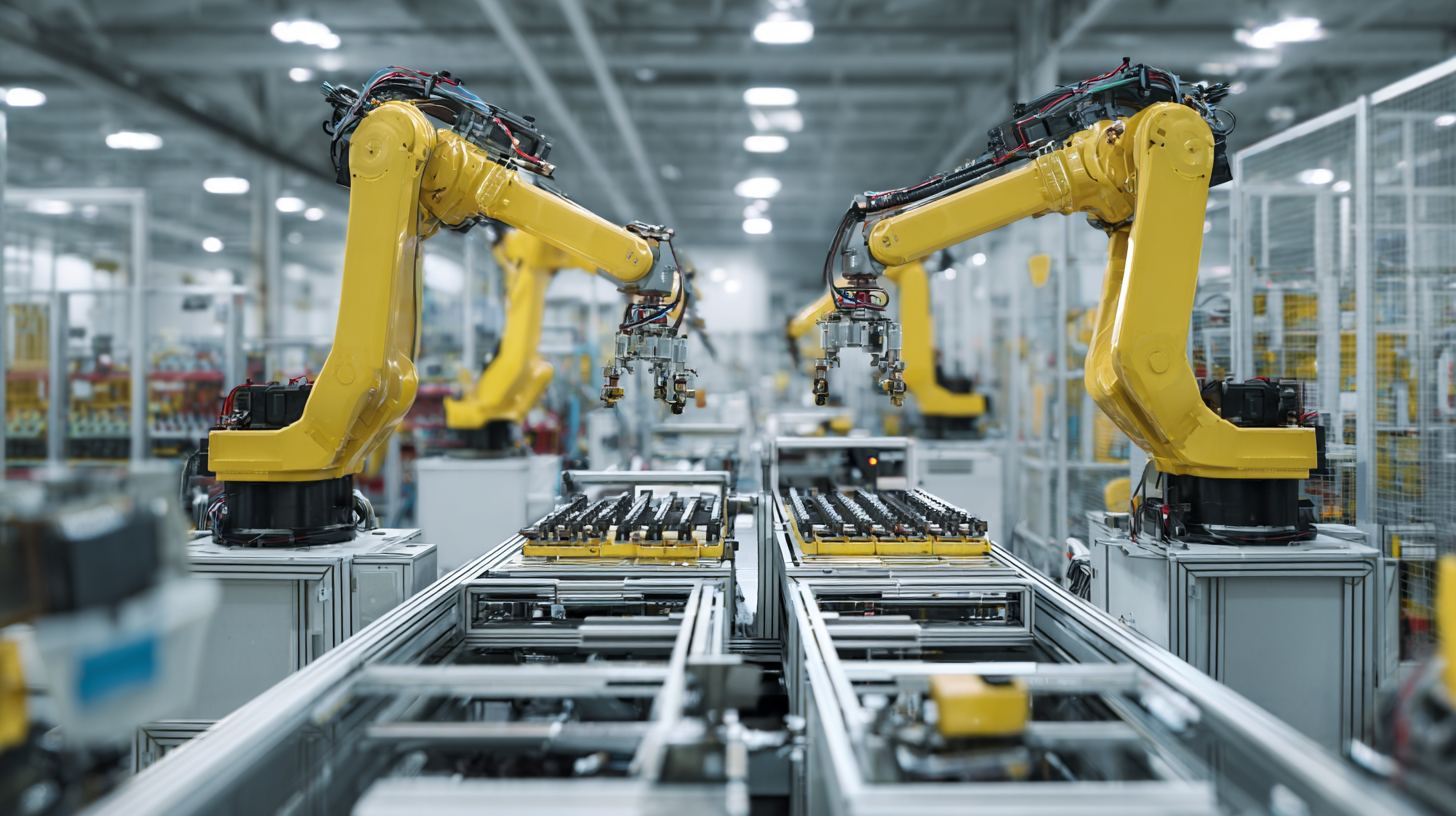

Automation has become a cornerstone of modern manufacturing, playing a critical role in streamlining processes and enhancing operational efficiency. According to a report by McKinsey, up to 45% of work activities could be automated with current technology, potentially leading to substantial boosts in productivity. By implementing automation machines, manufacturers can reduce cycle times significantly, increase throughput, and minimize human error, all of which contribute to improved product quality and consistency.

Moreover, the International Federation of Robotics noted that the global sales of industrial robots reached an all-time high in 2021, driven by increased demand for automation across various sectors. This surge reflects a widespread recognition that automation not only optimizes workflows but also allows manufacturers to respond more swiftly to market changes. In an era where customer expectations are continually shifting, automation stands out as a vital strategy for businesses aiming to maintain competitiveness and operational agility.

Why Automation Machines Are Essential for Modern Manufacturing Success - The Role of Automation in Streamlining Manufacturing Processes

| Automation Type | Efficiency Improvement (%) | Cost Reduction (%) | Production Speed Increase (%) | Error Rate Reduction (%) |

|---|---|---|---|---|

| Robotic Process Automation | 30 | 25 | 40 | 50 |

| Automated Quality Control | 20 | 15 | 25 | 70 |

| Supply Chain Automation | 15 | 20 | 30 | 40 |

| Manufacturing Execution Systems | 25 | 18 | 35 | 60 |

| Predictive Maintenance Automation | 18 | 22 | 28 | 65 |

Key Technologies Driving Automation in Modern Factories

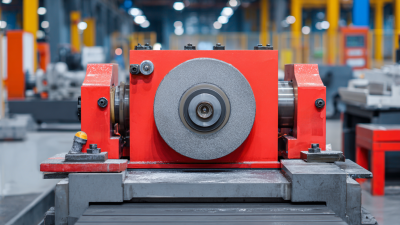

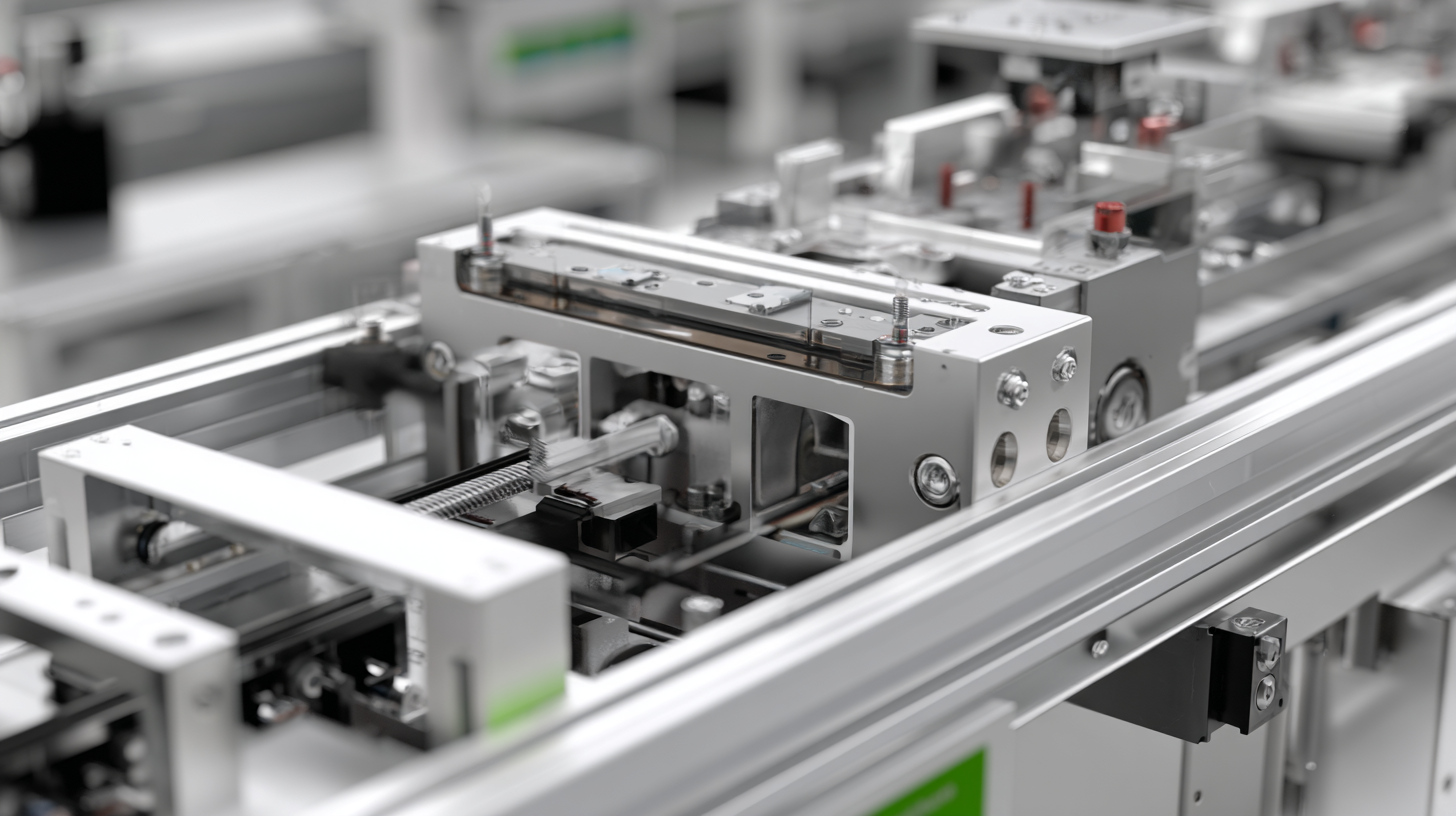

In the realm of modern manufacturing, automation machines have become pivotal to ensuring efficiency and competitiveness. Key technologies driving this transformation include Digital Twins, Industrial IoT (IIoT), and advanced robotics. Digital Twins facilitate real-time simulations of manufacturing processes, allowing manufacturers to optimize workflows and foresee potential issues before they arise. This predictive capability leads to reduced downtime and improved overall productivity.

Industrial IoT further enhances manufacturing systems by connecting machines and devices, promoting seamless data flow throughout the production line. This interconnectivity enables smarter decision-making driven by analytics and real-time insights. Additionally, industrial robots are revolutionizing assembly lines, handling tasks with precision and speed that significantly outpace manual labor. Together, these technologies not only bolster operational efficiencies but also pave the way for innovative practices such as predictive maintenance, which relies on smart sensors to monitor equipment health and prevent failures. Through these advancements, automation is redefining contemporary manufacturing success.

Benefits of Implementing Automation for Competitive Advantage

Automation has become a driving force in modern manufacturing, offering significant benefits that create a competitive advantage for businesses. According to a report by McKinsey, companies that adopt automation can improve productivity by up to 30%. This increase can be attributed to faster production times and reduced human error, ultimately leading to higher-quality products and greater customer satisfaction.

Manufacturers equipped with automation technologies are better positioned to respond to market demands swiftly, enabling them to stay ahead of competitors.

Tips for implementing automation effectively include starting with a thorough assessment of your current processes to identify bottlenecks that automation can address. Investing in employee training is crucial; a well-informed workforce will leverage automation tools efficiently, maximizing their benefits. Additionally, consider phased implementation: begin with low-risk, high-impact areas before gradually expanding automation across other segments of production.

Furthermore, a study by the International Federation of Robotics suggests that industries utilizing automation technologies see a yearly increase in output by approximately 14%. This heightened efficiency not only boosts profitability but also allows manufacturers to innovate and expand their product offerings. By harnessing the power of automation, businesses can not only keep pace with industry changes but also redefine them.

Challenges and Solutions in Adopting Automation Machines

The integration of automation machines in modern manufacturing presents several challenges that organizations must navigate to reap the benefits of increased efficiency. One significant challenge is the initial investment cost. Small and medium-sized enterprises often find it daunting to allocate resources for sophisticated automation systems. To address this, manufacturers can explore leasing options or phased implementation strategies that allow them to gradually integrate automation without overwhelming their budgets.

Another critical barrier is the skills gap in the workforce. As automation technology evolves, employees must possess the necessary skills to operate and maintain these advanced systems. Companies can overcome this hurdle by investing in training programs that upskill their current workforce and attract new talent well-versed in automation technology. Collaborating with educational institutions to create tailored courses can also ensure a steady pipeline of skilled workers ready to handle automation tools, thereby facilitating a smoother transition into an automated manufacturing environment.

Automation Machines in Modern Manufacturing

Future Trends: The Evolution of Automation in Manufacturing by 2025

As we approach 2025, the landscape of manufacturing is undergoing a significant transformation driven by advancements in automation and artificial intelligence. The upcoming IIFES 2025 exhibition showcases the evolution of automation technologies, focusing on artificial intelligence's role in reshaping control and measurement processes. Current trends suggest that the global AI manufacturing market is expected to grow from $760 billion in 2025 to over $623.3 billion by 2032, indicating a robust compound annual growth rate of 35.1%. This rapid expansion highlights the critical role AI will play in allowing manufacturers to boost productivity and enhance operational efficiency.

Moreover, the push for automation is essential not only for productivity but also for addressing challenges such as supply chain disruptions and labor shortages. A recent report indicates that 95% of manufacturers are now investing in AI technologies to navigate these economic uncertainties. As factories evolve into "lighthouse factories", exemplifying cutting-edge automation practices, the integration of smart technologies will be paramount. The industry is already seeing automation spending peak in process industries, where intricate procedures require precision and reliability. These trends underscore automation's indispensable role in achieving manufacturing success in the coming years.